Reaching into the fridge or cupboard at dinnertime, we don’t often think about the process which sees our favourite foods go from concept to kitchen.

But, more often than not, when you pick up jars and bottles of ketchup, chutney, dressing or sauce at the supermarket, the ingredients and flavours started life inside the imagination of someone like Darren Sivewright.

Working as a development chef for Baxters, makers of some of Scotland’s favourite soups, condiments and relishes, Darren spends his working week devising new and unique ways to bring produce to life – and he admits getting paid to cook and eat is one of the best jobs in the world.

“At school I was placed in work experience at my local restaurant, and afterwards they offered me a part-time job,” explained Darren, who is originally from Fraserburgh, and has been working for Baxters for almost a decade.

“I started off peeling vegetables and I stayed there right up until I left high school, when I began working full-time in the kitchen and started a college course.

“Then when I graduated from college I moved away from home to start working in different restaurants, and I’ve never looked back since.

“I’m so lucky that I get paid for my hobby – there’s not many people who get paid to do a job they absolutely love! It really is so rewarding.”

Inside Darren’s kitchen, the clever chef uses his years’ of experience to create recipes for everything from traditional jam and chutney to canned soups and salad dressing. And every single Baxters ready-made food starts life the same way – with Darren and his wooden spoon.

However, there are a few more steps before his meals make it to your dining table.

He said: “I start in the kitchen making the recipes as I would if I was just working in a regular restaurant. Then I spend time fine-tuning the flavours and getting the balance right.

“Once the recipe is ready, we sit down with food technologists, who take my kitchen version and adapt it for the factory. There’s a lot that goes into that process, because when you scale up the ingredients, you have to get the right balance and source the correct quality of ingredients.

“Obviously, the process is really different – in the kitchen, it’s just me with a pan and a wooden spoon, whereas in the factory, the recipes are made in a huge steam cooking vessel and the food wooshes through pipes and fillers. So, you need to take all that into account to make sure the end product is as good as the original.”

He added: “I would be lying if I told you I understood all the science behind it, but I’m fortunate that I’ve got a really, really good team here that do all that sort of stuff for me!”

One of Darren’s latest creations is a range of salad dressings, which each feature a key fermented ingredient to promote good gut health. It’s innovative and unusual ideas, like the Super Good Dressings, which Darren finds the most rewarding to develop.

And even after countless recipes and thousands of ingredients, he still gets a thrill when he sees one of his products in the shops.

“I am literally paid to go and eat in restaurants, visit food markets and meet other chefs, so I can pick up all the new trends and bring them back to our kitchen,” he continued. “It’s really important for us to do that because tastes and trends move so quickly. For example, even just two years ago, people wouldn’t have thought veganism and plant-based were going to take off as much as they have today.

“We were one of the first to market with a plant-based canned soup, and the flavour combinations are really exciting. The Butternut Squash and Lentil Dhansak is filled with really vibrant ingredients such as lime and coriander – things you don’t expect in canned soup.”

He added: “It sounds really cheesy, but everyone I work with loves the products and is so invested in them.”

Baxters Super Good dressings available in Waitrose, RRP £2

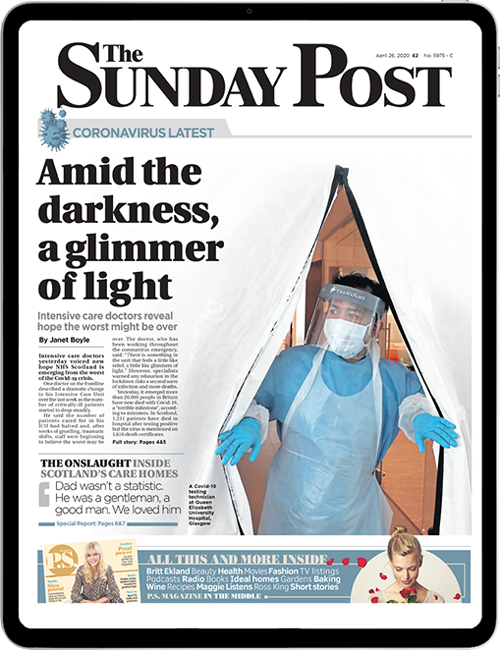

Enjoy the convenience of having The Sunday Post delivered as a digital ePaper straight to your smartphone, tablet or computer.

Subscribe for only £5.49 a month and enjoy all the benefits of the printed paper as a digital replica.

Subscribe