A Scottish company that turns plastic waste into roads and carparks has opened its first factory in Dumfries and Galloway.

MacRebur opened its new factory on Tuesday (today), creating 12 jobs.

Asphalt producers for the creation of roads is made by rubbish which has been granulated and mixed with an activator developed by the company.

The company say 1.8m plastic bags or 684,000 plastic bottles would be the equivalent of 1km of road, using the materials produced.

MacRebur’s mix allows the bitumen used in the production of asphalt to be extended and enhanced, reducing the amount of fossil fuel used.

It is hoped the idea could be replicated elsewhere and help tackle ocean pollution.

The idea for the plastic roads came after CEO, Toby McCartney was working in Southern India with a charity helping perple who work on landfill sites. Their job is to gather rubbish which can be reused for other things.

Some of the waste plastics retrieved by the pickers were put into potholes, diesel poured all over them, and the rubbish set alight until the plastics melted into the craters to form a makeshift plastic pothole filler.

After seeing this, the team came up with the innovative idea to take a mix of waste plastics, pelletise them and add them into the making of an enhanced asphalt road.

Mr McCartney said: “The opening of our first ever factory is an important milestone in our mission to tackle two issues – plastic waste and potholed roads.

“Our technology means that we can not only help solve the problem of plastic waste but also produce roads that cope better with changes in the weather, reducing cracks and potholes.

“That’s because our roads are more flexible thanks to the properties of the plastic used in them, so although a MacRebur road looks the same as any other, it has improved strength and durability.

“Our technology also means there are no plastic microbeads present in the mix and we can even recycle the road at the end of its lifespan, creating a circular economy that is sustainable and cost effective.”

MacRebur roads have already been laid around the world – from Australia to Yorkshire – using plastic waste processed by other companies.

However, the new factory will bring this processing in-house and provide a blueprint for others which the company is seeking to license in the UK and across the globe.

It has signed agreements for its first two licensed factories in Europe.

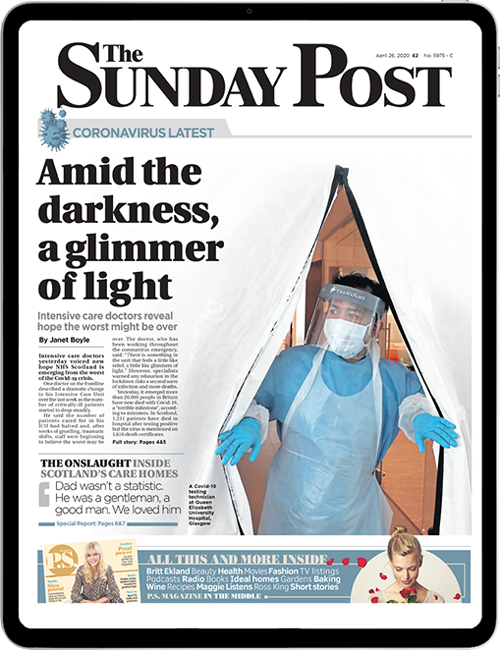

Enjoy the convenience of having The Sunday Post delivered as a digital ePaper straight to your smartphone, tablet or computer.

Subscribe for only £5.49 a month and enjoy all the benefits of the printed paper as a digital replica.

Subscribe