Empty shelves have become as common as tomatoes are rare but, according to experts, Scotland’s depleted supermarkets expose the fragility of our food supply chain.

Recent shortages of some fruit and vegetables have been attributed to crop failures in Europe and Africa brought about by extreme weather driven by climate change as well as the impact of Brexit, labour shortages, the ongoing war in Ukraine driving inflation and a sharp increase in energy prices that has left greenhouse growers struggling to turn a profit.

As the UK imports around 46% of the food it consumes and heavily relies on both imports and its agricultural sector to feed an ever-growing population, experts in Scotland believe vertical farming is a vital solution to concerns around global food security.

The method has been pioneered by the Edinburgh-based company Intelligent Growth Solutions (IGS) and scientists at the James Hutton Institute.

“If you balance imports and exports, the UK’s deficit in the trade of fruit and vegetables could be reduced annually by at least £1 billion by growing things internally with vertical farming,” said Derek Stewart who directs the Advanced Plant Growth Centre, a £27 million flagship project at the James Hutton Institute.

“The argument used to be that vertical farming could only grow salad or green crops but we’re starting to look at different protein crops like quinoa, beans and buckwheat. The market for plant-based proteins is enormous. To deliver a high-value, high-quality product at the required scale you need something like vertical farming.”

Across the country in warehouses, research facilities and farm buildings, growers, technicians and researchers continue to pioneer advances in vertical farming, whereby crops grow indoors in vertically stacked layers using LED lights and often water-based nutrient solutions (hydroponics) in place of sunlight and soil.

Instead of crop farmers being at the mercy of nature, vertical farming puts control into the hands of the grower. Elements such as light, temperature, humidity, air circulation, water, pH levels and nutrients can all be controlled at the touch of a button, even remotely.

This means crops can not only be grown faster and more efficiently to a consistently high quality using less space compared to traditional farming but can do so all year round without chemicals or pesticides.

Crucial research at the James Hutton Institute has benefited from recent investments including £17m from the Scottish Government to redevelop its facilities at Invergowrie and further research into growing sustainable barley crops and explore advancements in vertical farming.

“In most crops we’ve looked at we can reduce production time by 30-40% so you can grow much faster and, by manipulating the light or adding nutrients, we can make crops more nutritious such as being higher in vitamin C or zinc, and change and enhance the taste, density and colour,” said Stewart.

“Certain crops can continually bear fruit. IGS grew chillies for about 18 months, continually fruiting on the crop, which is unheard of, so the value you’re getting out of that crop is astronomical. Growers are seeing the advantage. By controlling the environment, it gives them a crop 365 days a year. Climate change is causing extreme weather variations that most plants can’t cope with but on a vertical farm you’re guaranteed a high-quality crop regardless of the weather and conditions outside.”

At a time when farmers face rising costs, labour shortages, bird flu and post-Brexit changes to support payments, vertical farming could aid rather than replace the struggling sector. Stewart added: “Farmers are businessmen so the first things they ask when they see the vertical farms are, ‘How much does it cost and how do I get one?’”

IGS, which designs, builds and exports vertical farms from six to 12 metres high around the world, has had 350 commissions across four continents and has grown from a staff of 20 pre-pandemic to 250 now. Its towers can grow 200 different varieties of edible produce including potatoes, carrots, radish, peppers, melon, strawberries, tomatoes, brassicas, broccoli and pak choi.

“We’re at the forefront of this and growing exponentially with the most sophisticated machine of its type in the world,” said the company’s CEO, David Farquhar, who has seen public attitudes towards produce grown in vertical farms shift in recent years.

“I spoke at a consumer show last October to find out what questions the public would ask, like, ‘Is this Frankenstein part two?’ but overall people said it gave them hope that it might be an answer to sustainably growing an increasing amount of food.”

Recent challenges impacting traditional farming methods such as decreasing soil health, floods, droughts and the impact of plant diseases and pests don’t apply to vertical farming.

“The amount of arable land that is still productive is decreasing every year and greenhouse operations have been massively challenged by rising gas prices,” said Farquhar.

“Vertical farms can be used in very arid areas. We use 250 times less water than a field. To grow a kilo of lettuce in a field you need 250 litres, about 25 litres in a greenhouse, but just one on a vertical farm.”

The method also requires less space so is ideally suited to urban and industrial environments. “The ratio of space required is generally 10,000 to one so what we grow in a 42 square metre footprint would require four hectares in a field. It can also reduce food miles since it allows you to grow, say, blueberries in Dundee in winter rather than flying them in from Peru.”

Farquhar added: “In terms of global food supply, vertical farming is complementary. It’s not going to compete with traditional farmers and growers but hopefully become part of their toolkit, like a tractor or combine harvester. As other forms of growing are increasingly challenged, and as our population heads towards 10 billion, we will need every method we can lay our hands on.”

Vertical farming isn’t without its drawbacks, including huge start-up and very high energy costs. With some food producers also reportedly cutting back on their use of greenhouses due to increasing energy process, and many greenhouse growers facing closure, the Hutton Institute and IGS are also looking into powering vertical farms with renewable energy.

“If you use renewable energy, it’s by far the most sustainable and productive system you can get,” said Stewart. Plans for a £2million renewable energy-powered vertical farm on Orkney have also recently been green-lit.

While vertical farming is big business, it is also growing on a smaller scale across Scotland to produce fresh and bountiful produce closer to home.

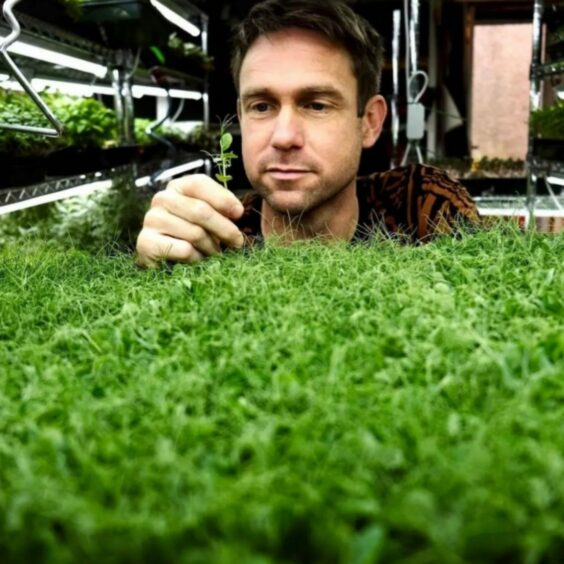

Daniel Oliveira is one of the few commercial vertical farm growers in Scotland. On his family farm in Duffus near Elgin, he grows stacked trays of nutrient-dense microgreens with a small 21 square metre vertical farm in a cellar.

His company, Rising Roots, grows and sells a variety of microgreens to chefs and other customers.

“I learned how to do it on YouTube by following different models and copying ideas and put them into practice in an old cellar in one of our farm buildings,” said Oliveira. “You can control everything like filtering the water, adding nutrients and using dehumidifiers and air conditioners to purify the air which creates a better product than if grown outside.”

Microgreens are the seedlings, or first leaves, of edible vegetables, flowers and herbs harvested within the first two weeks of growth. Packed with flavour and nutrition, they are a popular addition to salads and make delicate yet delicious garnishes in restaurants.

“We grow around 20 different varieties including pea shoots, sunflower seeds, broccoli and radishes and can produce up to 15 kilos of microgreens per week,” added Oliveira.

In a bid to make his enterprise more cost-effective and sustainable, Oliveira recently crowdfunded enough seed money to expand his business by converting a disused farm building onsite. He also hopes to eventually use wind turbine energy to help power his enterprise.

Oliveira added: “I want to carve a path for the future of sustainable farming and highlight an approach to growing that is kinder to the environment, reduces carbon, promotes a circular economy, limits carbon miles and ultimately provides an optimum health food.”

10,000 trees grow in an area the size of a snooker table

Vertical farming isn’t just transforming the way we grow food. It can also be used to grow botanicals and plants for use in skin care products and perfume, as well as pharmaceuticals and even trees and gin.

The James Hutton Institute has been experimenting with how vertical farms can become “green factories”.

“You can start growing the next generation of pharmaceuticals in crops,” said Derek Stewart of the institute’s Advanced Plant Growth Centre. “There’s a company in Canada growing Covid vaccines in plants using vertical farming.

“Vaccines and pharmaceuticals are made using great fermentation vats that run on huge amounts of energy. We’re looking at plants as a green factory; a huge set of chemical reactions we can use to produce pharmaceuticals.

“You can take the gene and put it into the plant, which converts that gene into a protein or chemical to a very high quality, but very cheaply. When harvested, it comes out at an incredibly high purification level so doesn’t need much of a tidy up before it is tableted or pelletised into a treatment.”

IGS has also been working with Forestry and Land Scotland to speed up the process of reforestation by growing tree saplings in vertical farms.

“They grew about six times faster than in a greenhouse at two-thirds the cost and our wastage rate on early trees growing out is less than 10% so much lower compared to commercial forestry,” said David Farquhar of IGS.

“On one growth tray, which is the size of a snooker table, we can grow 10,000 early-stage trees. There are 50 trays in a nine metre-high tower which means we can grow half a million trees in the space of 42 square meters.”

Stewart added: “People that want to re-wild areas will look to vertical farming systems to produce those types of plants.”

Enjoy the convenience of having The Sunday Post delivered as a digital ePaper straight to your smartphone, tablet or computer.

Subscribe for only £5.49 a month and enjoy all the benefits of the printed paper as a digital replica.

Subscribe © Ian Georgeson

© Ian Georgeson