When the crossing opens later this year it should bring blessed relief to commuters and frustrated businesses after the chaos caused by the closure of the Forth Road Bridge.

It showed the critical importance of a motor transport link across the River Forth.

We’ve taken a behind-the-scenes peak at Scotland’s new beauty.

- The Forth Road Bridge, opened in 1964, is used by 60,000 vehicles a day. Inspections back in 2004 found that a tenth of the strength of the cables had been lost to corrosion.

- With fears over the impact of major works, it was decided that the Bridge was no longer viable as a long-term main crossing and the new bridge was planned. The impact of a major closure was shown on December 4 last year when a fault was found that led to a full, then partial, closure until February 20.

- The new bridge, to the west, was announced in December 2007, to be complete by 2016. Work began in November 2009.

- The design chosen was pioneering. At 1.7 miles, it’s the longest three-tower, cable-stayed bridge in the world.

- The bridge will cost between £1.35 billion and £1.4 billion. The original estimates were up to £4.2bn for a much wider bridge with dedicated public transport lanes.

- But the existing Forth Bridge will now be used for buses, cyclists and pedestrians and will reduce the size, and therefore cost, of the new crossing.

- The new bridge is 207 metres, or 683ft, above high tide. It’s 50 metres, 164 feet, higher than the Forth Bridge and also the Humber Bridge, previously the two highest in the UK. It requires 150,000 tonnes of concrete, the same amount used for the Olympic Park and Athletes Village for London 2012.

- The 30,000 tonnes of steel is twice the weight of the world’s largest passenger ship, the Oasis of the Seas.

- The combined steel required for North and South viaducts weighs 7,000 tonnes, enough to make another 23 Kelpies sculptures.

- The 23,000 miles of cabling would almost stretch round the world.

- Almost 10 million man hours will have been spent on construction.

- It has two lanes of motorway and a hard shoulder in both directions.

- Shielding will avoid the need to close the bridge during high winds. Cables can be replaced without closing it too.

- Drivers will enjoy the smooth drive as it’s a continuous surface.

- Before the towers started rising from the Forth in the summer of 2013, foundations had to be put in place more than 40 feet down on the river bed.

- The steel caissons – or moulds – to pour the concrete for the foundations were the height of an eight-storey building. Despite the size, there was a margin of error of just one inch when lowering them into place. It took 15 days of pouring concrete 24 hours a day to fill each one. It was such a mammoth operation it set a new world record for underwater concrete pouring.

- Spectators have been urged to take pictures of themselves and upload them to become part of a Frame The Bridge initiative. The photos will be part of an online People’s Bridge mosaic.

- More than 35,000 votes were cast and 7000 different names suggested for the bridge. Caledonia, St Margaret’s, Firth of Forth and Saltire were all popular. But Queensferry, with 35% of the vote, pipped Caledonia’s 31%.

- 18-year-old Keir Stanton made history when he started work on the new crossing. He became the third generation of the same family to work on one of the Forth bridges. His great-grandfather John McGee worked on the Forth Bridge in the 1880s and his grandfather on the Forth Road Bridge in the 1950s.

- Each of the sections lifted into place weighs 750 tons, 250 tons is steel and the remainder concrete. They need to be positioned one at a time either side of the towers to balance them.

- The plan is to have the first traffic on the bridge in December.

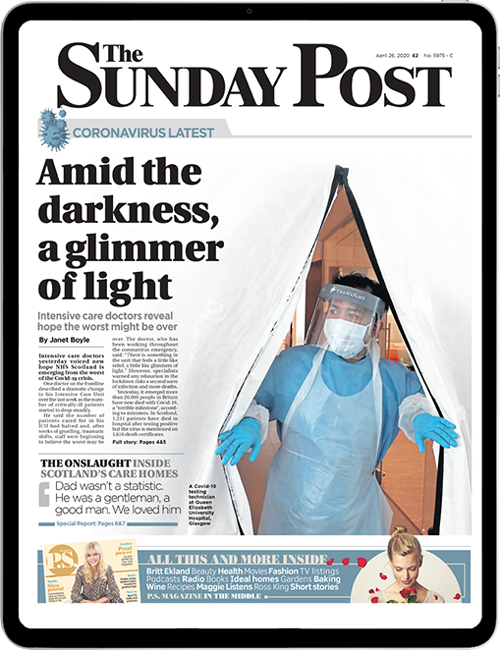

Enjoy the convenience of having The Sunday Post delivered as a digital ePaper straight to your smartphone, tablet or computer.

Subscribe for only £5.49 a month and enjoy all the benefits of the printed paper as a digital replica.

Subscribe